- Nederlands, Belgique / België

- Česky, Česká republika

- Deutsch, Deutschland

- Español, España

- Português, Portugal

- English, Europe

- Français, France

- Italiano, Italia

- Magyar, Magyarország

- Nederlands, Nederland

- Deutsch, Österreich

- Polski, Polska

- Română, România

- Suisse / Schweiz / Svizzera

- Svenska, Sverige

- Suomeksi, Suomi

- Türkçe, Türkiye

- English, United Kingdom

- Slovenská, Slovak

-

Worldwide

Subcontractor Navigates Automotive Evolution with Mitutoyo

Specialising in the production of prototype components and complex small batch runs for the automotive sector, Birmingham based Advanced Engineering (UK) Ltd has always maintained its ethos of investment in technology to deliver quality components with lead times beyond the capabilities of its competitors. This philosophy has resulted in the company placing its trust in metrology equipment from Mitutoyo.

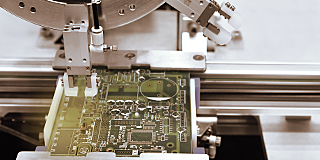

As a manufacturer that works primarily with automotive OEMs as well as F1 engine manufacturers, aerospace, defence, rail and nuclear business sectors; Advanced Engineering prides itself on its quality management systems that include and ISO: 9001 accreditation, and can comply with all requirements from other Industry specific requirements from the TS: 16949 Automotive standard and AS: 9100 standard to meet varying Customer needs and Expectations. Spending over £3m on new equipment in the last five years, two of the most recent arrivals at Advanced Engineering Ltd include a Mazak VARIAXIS i-700 5-axis machining centre that arrived in November and a QUICK TURN 250 turning centre. This now gives the company a total of 19 Mazak machines that undertake everything from complex prototype work through to automotive production projects that include all levels of PPAP, APQP, FMEA, SPC’s and full supply chain management – Mitutoyo is central to these strategies.

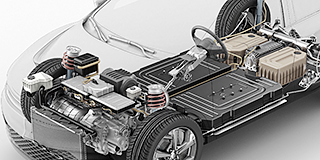

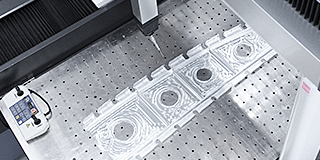

Producing everything from CAM covers, cylinder blocks, control arms, pump housings, decorative door linings and prototype wheels for automotive OEMs, turnaround times are a critical factor for Advanced Engineering. This is why the combination of Mazak 5-axis machine tools, hyperMILL CAM software and a complete suite of Mitutoyo inspection equipment are central to expediting high quality components through the business at breakneck speed.

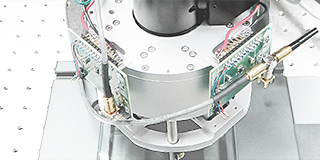

The relationship with Mitutoyo dates back over 20 years with a complete range of hand tools and the first Mitutoyo CMM, a Crysta Apex 9106 arriving on site some 15 years ago. Still reliably running up to 12 hours a day, the Apex 9106 was followed by a smaller Crysta Apex 574 CMM over 8 years ago. The second machine was acquired to relieve the bottleneck of work that was building on the company’s first CMM.

As the Quality Manager at Advanced Engineering, Mr Andrew Stevens says: “All our work is based around customer requirement. We deal with a single one-off prototype product, through to support, NPI products and new product model launch. We work closely with Tier 1 manufacturers and OEMs and the diversification into electrification is being done by our customers, we almost ‘engineer to print’. So, where our customers are protecting themselves and looking at other products sectors, such as light-weighting vehicles – this is having a dramatic effect on the work we are seeing here. We are being shielded by our customers, but also seeing a change in our products to suit the evolving marketplace.”

The smaller, more cost effective Apex 574 CMM has not only relieved capacity, it was the perfect product for the changing market demands of the automotive sector. As Mr Stevens continues: “Our work initially evolved beyond cylinder head and engine blocks into turbos and other small complex powertrain parts and the Apex 574 proved an excellent solution with its compact footprint. However, our workload has continued to evolve even further with more body-in-white work and in particular suspension parts being manufactured. With the requirement for additional measurement capacity, we once again opted for a Mitutoyo solution, the Crysta Apex-S CMM. We bought the Apex-S as we wanted the new CMM to be capable of mirroring the Apex 9106 machine, something that would give our metrology team more flexibility, reduced set-ups and extra capacity as and when required.”

Commenting upon the continual changes in the automotive sector and how Advanced Engineering is addressing the issues from a measurement perspective, Mr Stevens says: “We got to a point where our Apex-S and Apex 9106 have been working side by side with the smaller Apex 574 being reserved for smaller parts, providing much needed capacity at busy periods. However, a lot of our OEM customers and their cylinder head work has taken on a new level of dimensional tolerances over the years. To facilitate this, we swapped out the TP20 touch probes that operate on a touch trigger mechanical mechanism to the new continuous contact SP25 Renishaw system. Mitutoyo fully retro-fitted the system to both our Apex 9106 and Apex-S CMMs and this gives us precision to 2 microns. Furthermore, by continuously scanning the complex features of parts, we are getting a full 3D scan of the components and this can be compared directly with the CAD model. All this is innovatively done with the Mitutoyo MCOSMOS operating software with full certification and traceability for our customers.”

With 85% of work at Advanced Engineering passing through the metrology department, Mitutoyo was once again on hand when yet more demands filtered downstream. As Mr Stevens says: “Surface finish has become more prominent in the automotive market with seal seat surfaces and waveforms on engine blocks and cylinder heads taking on more stringent controls. To measure surfaces, we approached Mitutoyo and they recommended the SurfTest SJ-410 Series portable surface roughness tester. OEMs are now placing more 100% inspection demands on critical features like cylinder head bores and to once again relieve capacity and reduce set-ups on our CMMs, the SurfTest SJ-410 was the perfect addition.”

Referring to the relationship with Mitutoyo, Mr Stevens continues: “Our tie-up with Mitutoyo goes back for many years. We have always used Mitutoyo through the reliability and quality of the products that they supply and that goes right the way through from hand tools to CMMs. We have an amazing service contract with Mitutoyo and they carry out all our calibration work. We wouldn’t trust anyone else to calibrate our equipment. It’s a longstanding relationship that has been based on trust, good service and the level of product innovation.”

“We chase microns on the shop floor and we need to be able to repeatably be able to measure to microns and be confident that each measurement is accurate. With the type of products we are producing here, we are pushing the bounds of our CMMs through varying changing customer requirements. So, when we see new customer requirements and we need the CMMs to do something slightly different to meet those requirements, Mitutoyo have engineers on the end of the phone, so we can get their technical support to resolve challenges very quickly.”