- Nederlands, Belgique / België

- Česky, Česká republika

- Deutsch, Deutschland

- Español, España

- Português, Portugal

- English, Europe

- Français, France

- Italiano, Italia

- Magyar, Magyarország

- Nederlands, Nederland

- Deutsch, Österreich

- Polski, Polska

- Română, România

- Suisse / Schweiz / Svizzera

- Svenska, Sverige

- Suomeksi, Suomi

- Türkçe, Türkiye

- English, United Kingdom

- Slovenská, Slovak

-

Worldwide

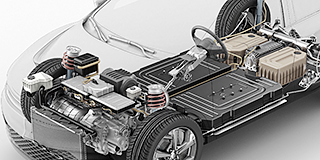

Co-founded in 2007/8 by David Cox, a Formula 1 (F1) engineer, Shoreham-on-sea, based Cox Powertrain Ltd, have developed the world’s first 300hp marine diesel outboard engine - the CXO300. The inspiration behind the ingenious engine was the global military’s drive to adopt diesel as a preferred fuel and to reduce or indeed end its use of gasoline.

Mitutoyo aids Cox Powertrain’s Quality Function

The exciting engine concept sparked interest from the UK Ministry of Defence (MOD) and the US Government, for diesel outboards and prompted the Defence Science and Technology Laboratory (DSTL) to provide £2.5m in funding, in addition to invaluable technical assistance for developing the CXO300 for marine use. The company now has close links with the US Coast Guard, and the US, Dutch, Swedish and Australian Navies. The CXO300 delivers increased responsiveness, enhanced fuel efficiency and improved safety in an engine that outperforms conventional diesels. Reduced size and weight belies the impressive power from a four cylinder, eight piston supercharged, 2-stroke diesel engine that generates an impressive 300hp.

Due to launch in 2018, the CXO300 will have to undergo a series of demanding trials, in addition to satisfying the IMO, Tier 3 EPA and EU emissions compliance process. Whilst meeting military marine needs, the innovative new diesel outboard is expected to be a great success with commercial professionals around the world, as well as the marine leisure sector. Having been designed to meet the extremely challenging requirements of the demanding global military sector and to provide reliable service in the harshest of marine environments, the highest standards of quality are applied to the CXO300’s manufacture. The use of advanced production techniques, the application of extremely tight tolerances to its components and a rigorous inspection regime enables the CXO300 to achieve an extended working life when compared to current market offerings.

In addition to dimensional checks, given the potential for the generation of friction and wear in moving parts, particular attention is paid to components critical surface roughness parameters. Duncan Green, Cox Powertrain Ltd. Head of Procurement explained, “In addition to Petrol now not being permitted on-board military ships, it is also not allowed on many commercial vessels and superyachts. This has created a problem as currently no diesel outboard is currently available in the 250-350hp target market. In addition to being the same size and weight as gasoline equivalents, the CXO300 is designed to deliver better fuel consumption. A 3.7 litre capacity and reduced mass means there is no compromise on power compared to conventional diesels of similar power output, as well as being safer than comparative output gasoline engines.

“Given our targeted customers, the engine’s reliability and working life is particularly important. When compared to the current market offering, the CXO300 has an extended design life of 3000hrs. As the surface finish characteristics of the CXO300’s components have a massive influence on their performance, we recently searched for an advanced surface roughness tester that was able to deliver very precise results in the many surface roughness parameters that we use. After considering several alternatives, we found the answer to our needs in the Surftest SJ-500 from Mitutoyo. The advanced Mitutoyo instrument is able to inspect our parts in all of our surface roughness parameters, it is also able to work in many other parameters that we may possibly need in the future. The instrument has proven invaluable in upholding the quality of our manufactured components throughout our engine development period and will also be kept busy coping with anticipated production volumes.”

Ken Edwards, Cox Powertrain Ltd. Chief Inspector added. “As its menu-driven system is so easy to use, I was able to use all of the SJ-500 facilities immediately after its installation. It also helps that the unit has a high-resolution colour display with touch screen operation. The instrument’s automatic calibration function also gives me confidence in the precision of the reading that I achieve. In addition to working in all of the surface roughness parameters that we use, it also helps that the unit’s detector system can be mounted laterally for transverse measurements.”

Mitutoyo offers a wide range of high-quality surface roughness testers, from battery powered portable types that can be applied to any workpiece, irrespective of size, through to the most sophisticated laboratory type CNC instrument that makes measurements to state-of-the art accuracy and resolution standards.

The Mitutoyo Surftest SJ-500, as purchased by Cox Powertrain, is a high precision, high-performance surface roughness tester with a dedicated control unit. The instrument’s 7.5-inch, colour TFT LCD, large coloured icons and touch-panel controls make the display extremely easy to read and the instrument simple to operate. A built-in joystick on the control unit enables quick and easy positioning, in addition a manual adjustment knob allows fine positioning of a small stylus, particularly useful when testing features such as the inside surfaces of small holes. Setup is simple by means of a ISO roughness-standard input function, enabling complex setups to be entered easily by selecting the appropriate symbol from a menu. Aiding flexibility, the instrument can be used as a stand-alone unit or mounted on a robust stand.